I think the top is stable, and would recommend if you build a bench not to turn up your nose at wood with the pith in. Just be warned that there will be cracks. The cracks are not a problem unless you drop something small like finishing brads on your bench top. They will get lost in there, but structurally they make no difference to the bench.

I figure that while I have extra epoxy, I can just dump it in these cracks, and someday I will have a bench top with no cracks in it.

|

| Here is my bench top after I poured extra epoxy into some of the cracks. |

|

| Why three? I'll let you know as soon as I figure it out. |

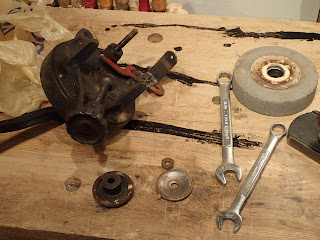

There was a surprise, in that one of them had a one inch arbor. That means it will fit a modern grinding wheel out of the box. The second one had a 5/8" arbor, and it fit a modern grinding wheel using the plastic bushings that came with it. In the past, I have found hand cranked gridners (including the first of this trio I found) have a 3/8" arbor, and need some real fiddling to make work. I had both of these running new wheels in five minutes flat.

|

| Lucky me, a one inch arbor. |

|

| 24 grit seems awfully course, but Larry knows his stuff. |

|

| Everything installed in no time flat. |

This Meda wheel, I have to say, is pretty awesome. The blade never got very hot, and the grinding went very quickly. Definitely an upgrade from my brown Norton wheel (80 grit, I think - maybe 40). The only thing is the grit seems to come off quickly. But, for the price, I think it would be worth burning through these wheels twice as fast.

|

| Here's my grinding set up using my saw bench. |

|

| Before |

With this in mind, I decided to make it flat, but not to waste time making it too smooth.

This was over before I really got a chance to photograph the progress.

I took a big wooden jointer set with a heavy cut, took passes front to back evenly across the grain for the whole length of the bench. Next I took shavings at a 45 degree angle across the top. Last, I went with the grain using a medium cut with my BU jack plane.

Done.

|

| After |

|

| Here is a close up of a crack that has been filled with black epoxy, then planed. |

So far I have yet to put finish on it, and I think I probably never will. Someday I might put a shelf on the bottom. The only thing it really needs is the sliding deadman, which I need about twice a year for the kind of work I do. So far I have gotten away without it. The bench is about 18" deep, maybe a little more, and a little over six feet long. I have upgrades still awaiting for the tail vice, and I have a nicer piece of elm waiting to be installed as a face vice, along with a Benchcrafted CrissCross.

Good stuff, Brian. I've been looking for a hand-crank grinder for a while. Just lost an auction on e-Bay last week. I really suck at e-Bay and hate it most of the time, but you never know.

ReplyDeleteI hope you didn't lose your auction to me!

DeleteThe trick with eBay is to be patient. Don't get frustrated and overbid. With hand tools, you also shouldn't get your nose bent out of shape if what arrives in the mail isn't really what you expected. "Sharp and ready to use," means something different to eBay sellers than it does to you and me.

I treat cracks the same with epoxy, works great and has never let mre down even outside on porch posts

ReplyDeleteBob